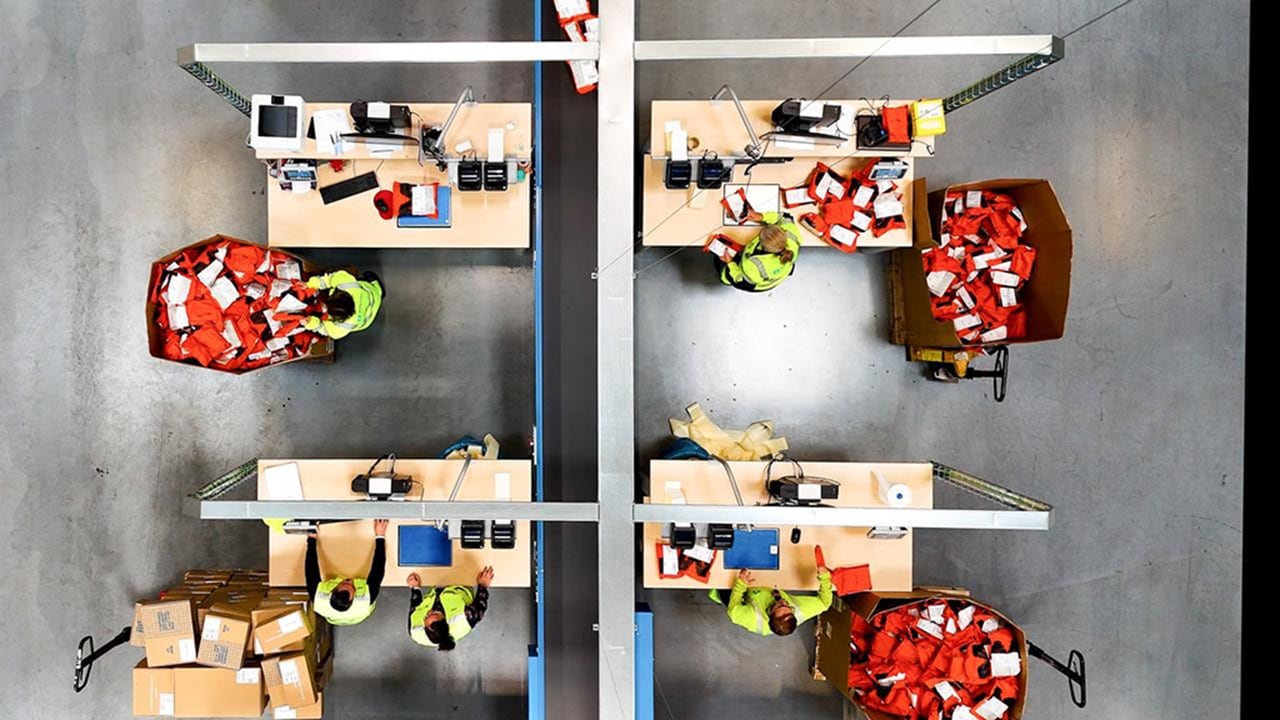

In the face of evolving trade policies and tariffs, businesses must adopt robust warehousing inventory strategies to maintain financial resilience. As the latest Logistics Manager’s Index (LMI) report indicates, inventory costs and warehousing prices are expanding at their fastest rates in years, driven by a surge in inventory levels as firms attempt to preempt tariff impacts. Here’s how strategic warehousing can help businesses navigate these challenges:

Transloading for flexibility and control

Retailers who transload goods at a destination port can choose to either send products directly to distribution centres or store them temporarily at intermediate warehouses. This flexibility is vital for mitigating uncertainty, as it enables the retailer to respond quickly to changes in demand and provides a strategic advantage by providing greater control over freight orchestration.

Push vs. pull models

Adopting a push model through transloading can enhance resilience by positioning closer to key markets, thereby reducing lead times and improving service levels. For example, a global apparel brand could use the push model to stock seasonal items in regional warehouses ahead of peak seasons, ensuring quick distribution, minimising the risk of stockouts, and reducing the impact of tariffs. Conversely, the pull model, often associated with intact container movements that stay sealed and untouched during transit, can provide cost savings but falls short in terms of the agility needed in a dynamic trade environment.

Multi-Channel inventory management

Leveraging multi-channel inventory strategies allows businesses to optimise their supply chains by dynamically allocating inventory across various channels—be it direct-to-consumer, wholesale, or retail. This approach not only improves service levels but also reduces the need for excessive safety stock, enabling companies to allocate stock based on real-time demand, thereby lowering carrying costs.

Bonded warehousing and duty deferral

To mitigate the financial impact of tariffs, businesses can utilise bonded warehousing solutions. By holding inventory in bond, companies can defer duty payments until the goods are needed, providing significant cash flow benefits. While certain classes of bonded warehouses can offer value-added services such as repacking, labeling, and quality inspection, it's important to note that this capability is not universally applicable across all bonded warehouses. Specifically, Foreign-Trade Zone (FTZ) and non-FTZ bonded warehouses require Customs and Border Protection (CBP) approval, either on a per occurrence basis or through a blanket authorisation, to manipulate goods while in-bond. This detail emphasises the importance of knowing the type of bonded warehouse being used to ensure compliance and properly prepare goods for their final markets. Additionally, both bonded warehousing and FTZs allow goods to be re-exported to other markets without facing U.S. tariffs.

Strategic warehousing locations

The choice of warehousing locations plays a critical role in managing tariff impacts. Establishing distribution centres (DCs) in strategic locations can help businesses avoid cross-border duties and streamline their supply chains. With Maersk’s integrated network, we support customers with a range of services spanning the United States, Canada, and Mexico. This network provides businesses with multiple sourcing and distribution options, enabling them to adapt quickly to market changes.

As some companies reshore manufacturing operations to the U.S. in response to global trade uncertainty and rising production costs, the need for robust domestic supply chain infrastructure is growing. This shift presents a significant opportunity to support retailers with agile, U.S. based warehousing and distribution solutions that align with their new production footprints.

Moreover, bi-coastal or tri-coastal warehousing strategies – which involve positioning inventory across two or three major U.S. coasts – can place goods closer to key markets. This approach reduces transit times, lowers delivery costs, and enhances service levels by enabling faster, more flexible fulfillment.

Partnering for resilience

Modern warehousing demands efficiency, adaptability, and resilience, which are essential for building financial resilience, especially in the face of challenges like tariffs. By leveraging transloading, multi-channel inventory management, bonded warehousing, and strategic location planning, companies can navigate the complexities of the current trade environment and maintain a competitive edge.

Partnering with Maersk means accessing a robust and adaptive warehousing network designed to meet today's logistics demands.

How can you make your logistics interconnected?

Reduce complexity with an all-in-one solution where your business only has to deal with one partner to service all your supply chain needs from start to finish. In disruptive times like these, it’s especially important to work with logistics providers who have asset control. This ensures the flexibility and visibility needed to adapt quickly across the supply chain.

Maersk’s integrator offering is designed with this in mind – delivering end-to-end resilience through connected controlled logistics.

Be ready for your supply chain strategy to go all the way! Discover more with Maersk Logistics Insights, and learn more about Contract Logistics or for more logistics trends and insights, read and download The Logistics Trend Map.

How can you be ready for anything?

Instability is on the rise, causing logistics to feel the pressure of the constant disruptions. Is your business resilient enough? Do you know what it takes to build resilient supply chains in today's world?

Learn how Maersk can help with logistics resilience.

未来,您想随时了解必读行业趋势吗?

您已经完成了,欢迎“登船”!

很抱歉,发送您的联系请求时出现问题。

请查看表单字段,确保所有已正确填写所有必填信息。如果问题仍然存在,请联系我们的支持团队以获得进一步的帮助。

未来,您想随时了解必读行业趋势吗?

使用此表格注册,即可直接在您的邮箱中接收我们的洞察见解,进入一个真正的综合物流世界。简单操作,即从我们为您量身定做的精选文章中获得启发,了解相关行业洞察信息。您可以随时取消订阅。

I agree to receive logistics related news and marketing updates by email, phone, messaging services (e.g. WhatsApp) and other digital platforms, including but not limited to social media (e.g., LinkedIn) from A. P. Moller-Maersk and its affiliated companies (see latest company overview). I understand that I can opt out of such Maersk communications at any time by clicking the unsubscribe link. To see how we use your personal data, please read our Privacy Notification.

By completing this form, you confirm that you agree to the use of your personal data by Maersk as described in our Privacy Notification.